Product Supply Code: NLAB-TECHNICALAB31016

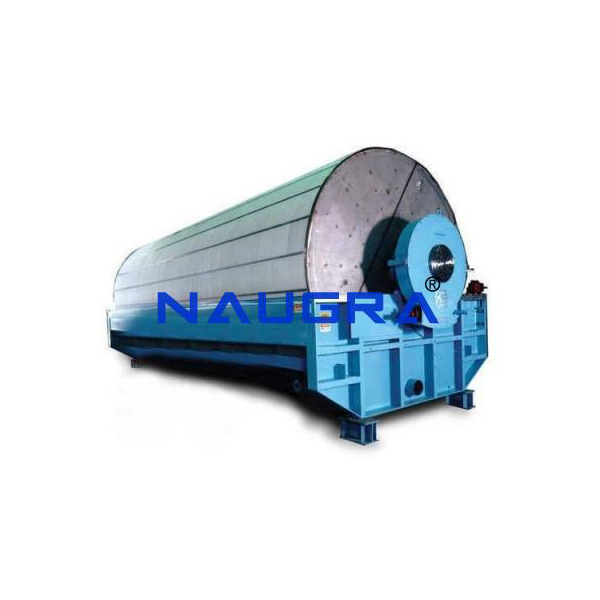

Product Name: Rotary Vacuum Filter

Tender Supply Category: Mechanical Operational Lab

The most common types of continuous vacuum filter is the rotary drum filter. A horizontal drum with a slotted face turns at less than 2 RPM in an agitated slurry trough. A filter medium, such as canvas, covers the face of drum, which is partly submerged in the liquid. Under the slotted cylindrical face of the main drum is a second, smaller drum with a solid surface. Between the two drums are radial partitions dividing the annular space into separate compartments, each connected by an internal pipe to one hole in the rotating plate of the rotary valve Vacuum and air are alternately applied to each compartment as the drum rotates. The set-up consists of stainless steel drum moving in gunmetal brackets and is divided in 6 compartments, covered by a Stainless Steel mesh. A canvas filter is used for filtration. The whole assembly is fitted with a SS trough in which a agitator is provided. To make the unit a self-contained a slurry mixing and feed arrangement, receiver tanks, vacuum pump, control panel are provided.

Experimentation:

To study the performance of a Rotary Vacuum Filter.

To study the operation of Rotary Vacuum Filter under vacuum.

To determine the specific cake resistance and medium resistance.

Utilities Required :

Electric Supply: Single phase, 220 V AC, 3.5 kW.

Water supply.

Drain.

Slurry required to performing experiment.

Technical Details :

Filter Drum: Material Stainless Steel, Dia. 250 mm, Length 350 mm.

Mesh: Material Stainless Steel

Filter: Canvas Cloth

No. of Zones: 6 Nos.

Drive for Drum: FHP motor coupled to a Reduction Gear Box

Trough: Material Stainless Steel, Compatible capacity.

Trough Agitator: Material Stainless Steel, driven by FHP motor with Reduction Gearbox.

Slurry Tank: Stainless Steel, capacity 75 Ltrs.

Slurry Pump: Gear Pump with ½ HP motor

Slurry Tank Agitator: Stainless Steel Impeller with SS Shaft coupled to FHP motor and Reduction Gear Box

Filtrate Receiver: Material Stainless Steel, Capacity 10 Ltrs. (2 Nos.)

Vacuum Pump: Liquid Ring type coupled to a 1 HP Motor

Piping: GI and PVC size ½

Rotary Vacuum Filter Quality Assurance: We being a leading Rotary Vacuum Filter manufacturer from India. NaugraLabEquipments are actively involved in providing precision equipments of premium quality to clients across the globe for Testing Lab and TVET Technical Lab, Industial Training Institutions. We always utilize the most advanced and sophisticated technology for production process of Rotary Vacuum Filter and supply exceptional range of other products like Rotary Vacuum Filter for tender supply from India.